In the new generation of water coolers, a bldc motor has been used, due to the use of these motors, the major problem of the old coolers that worked using a dynamo belt has been solved. The main problem of the old coolers was their high electricity consumption, the cause of which was their motor. The dynamo motor, due to the belt it had, caused the blades inside the cooler to rotate, and the cool air inside the cooler entered the interior through the channels.

This same old system caused the electricity consumption of water coolers to be very high, but now brands such as Cool Art have entered the market and introduced BLDC motor technology to the water cooler industry. and explain its benefits to you.

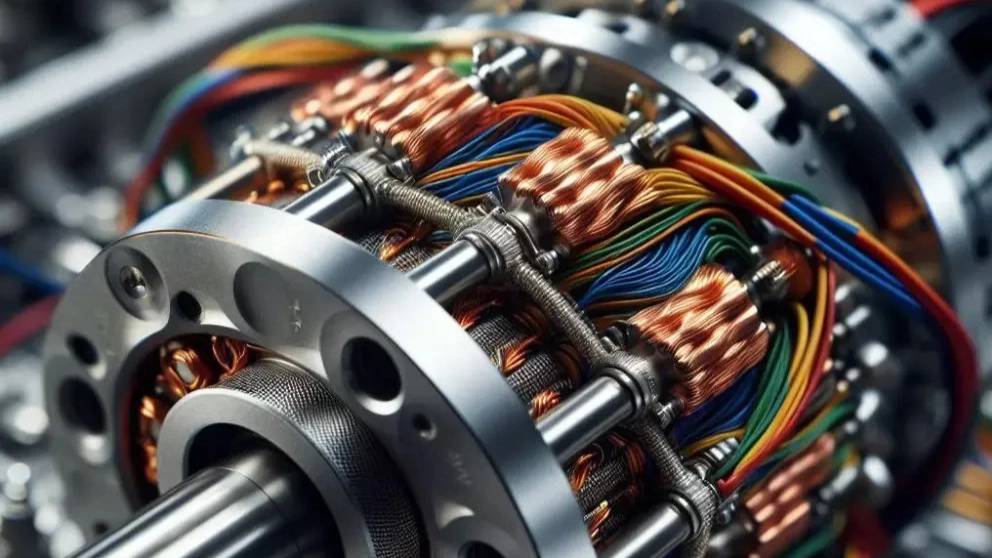

BLDC engines in water coolers

One of the major problems of water coolers in the summer is the issue of high electricity consumption, which today has been partially controlled by the new generation of BLDC motors, which stands for Brushless DC Motor. These engines are known as one of the advanced innovations in this industry. In old engines, the blades of the cooler fan are rotated by a belt and pulley, and the cool air is directed inside through the channel. But in water cooler BLDC motors, coils and adjustable frequency technology are used to generate the magnetic field. In this type of cooler, the belt and money have been removed, and the inner space of the cooler is quiet, and this causes the weight of these coolers to be less.

1%saving using BLDC engines in water coolers

In this type of cooler, the placement of the motor has been changed, and as a result, the need for a belt to transmit power has been eliminated. In addition, the body of this cooler is made of polymer, which retains energy much better than metal.

Apart from that, cellulose pad is used instead of cloth, which has two major problems. First, cellulose pads absorb the surrounding heat much better than cloth and have a more optimal performance in cooling the environment, and this itself reduces energy consumption. Second, unlike common pads, these pads require less replacement.

By using this water cooler, 20% of water consumption and 40% of electricity consumption are optimized. Adjustable motor speed, continuously, due to having a driver (electronic start and control circuit) in BLDC motors, is another feature of this cooler.